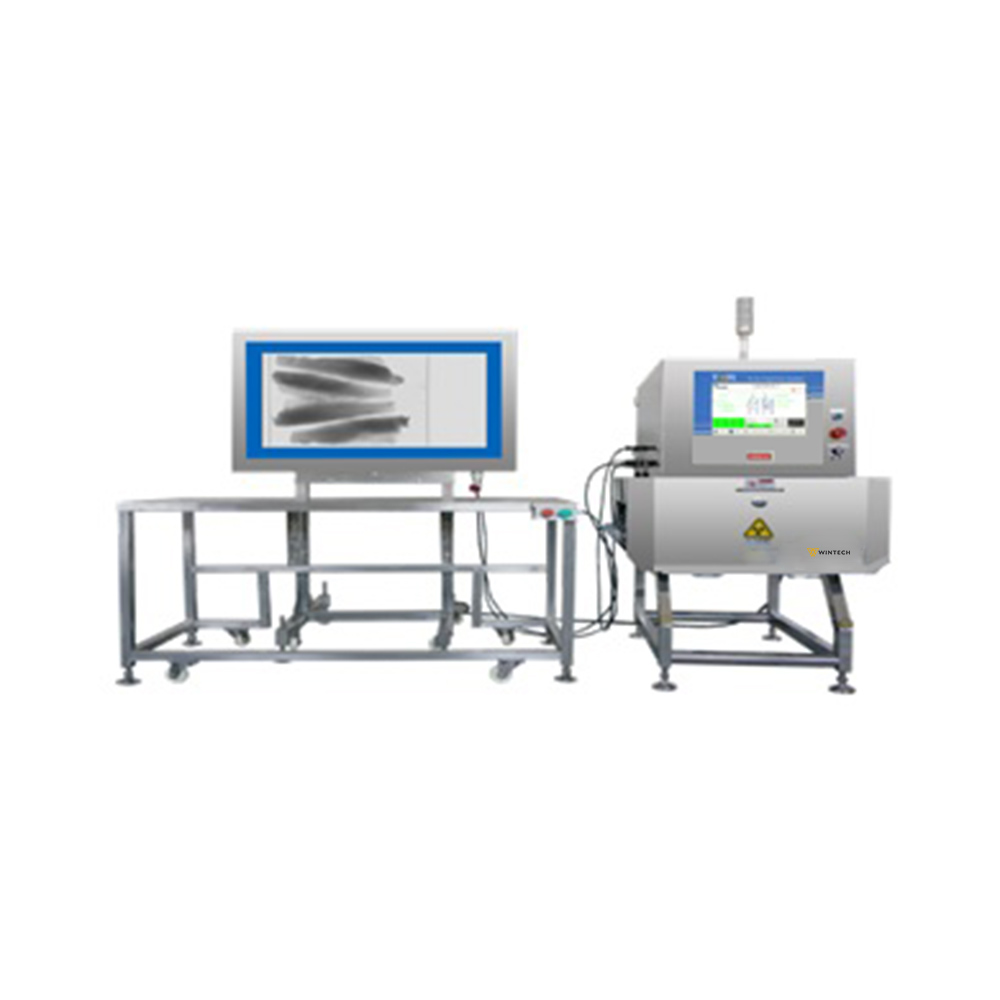

STANDARD X-RAY SYSTEM

STANDARD X-RAY SYSTEM

INTRODUCTION

Standard X-Ray systems are used for a variety of applications in food industries

An X-Ray system is an electronic instrument which detects the presence of metallic & non-metallic in packed or loose products. X-Ray system is useful for finding metallic & non-metallic contamination in products.

FOCUS INDUSTRIES

| Food Packing | |

| Pharmaceutical industry for detection of Non-Metallic contamination |

SPECIFICATION

| Model | Standard END-EXR Series |

|---|---|

| Standard | 2480, 4080, 4080L, 4080S, 4080SL, 4080SH, 5080SH, 6080SH |

| X-ray Generator | MAX, 80kV, 150W, MAX,80kV, 210W, MAX.80kV, 350W |

| Inspection Width | 240mm, 400mm, 500mm, 600mm |

| Inspection Height | 100mm, 160mm, 100mm, 160mm, 100mm, 220mm, 250mm, 300mm |

| Best Inspection Sensitivity (without product) | Stainless steel ball ᶲ 0.3mm, Stainless steel wire ᶲ0.2*2mm, Glass Ceramic ball ᶲ1.0mm, Stainless steel ball ᶲ0.4mm, Stainless steel wire ᶲ 0.2*2mm, Glass Ceramic ball ᶲ 1.0mm |

| Conveyor speed | 10- 60m/min, 10- 40m/min |

| Operation system | Window7 |

| Protection Method | Soft Curtain |

| X-ray Leakage | <1 µSv/h (CE Standard) |

| IP Rate | IP66(Under belt) |

| Working Environment | Humidity: 30-90% no dew Temperature:- 10~40 deg C) |

| Cooling Mode | Industrial air conditioning |

| Rejecter Mode | Sound and light alarm, belt stop (Rejecter optional) |

| Air pressure | 0.8 Mpa |

| Power supply | 1.5kVA |

| Main Material | SUS304 |

| Surface Treatment | Mirror polish/Sand blasting |

Reviews

There are no reviews yet.